Spray Equipment & Procedures

TPR2 paints can be sprayed with standard air or airless spraying equipment. The specifics below provide the critical characteristics for choosing the right equipment. TPR2 offers pre-assembled, ready to use sprayer setups at www.paintproject.com

Please remember some important items relative to your application: Humidity and temperature will play a large role in efficient and correct drying of the coating. Keep in mind you will be introducing moisture while foam and coating spraying and will need to get that moisture out. Please review and familiarize yourself with the attached ventilation procedure. VENTILATION PROCEDURE

Any ceiling application (we assume there will be horizontal and vertical surfaces in your job) goes on at 1/2 the stated max/coat thicknesses to prevent dripping. So, where 1 application coat might suffice on walls (to achieve the required .016" dft) without sag, The contractor will need to spray 2 thinner coats on a ceiling. This is conventional knowledge for spray people. In general, we recommend a 'tack' coat application of the coatings first, then a full coat will achieve the stated dry film thickness of .016". GET JOBSITE CHECKLIST

TPR2 defines its coating coverage's on 3rd party tests as Wet Film Thickness(WFT) and Dry Film Thickness(DFT). This is done so that the coating application will be accurate independently of the substrate and also easier to confirm compliancy with 3rd party test results. Remember, porous surfaces (fresh sheetrock, plywood, etc) will absorb more coating and thus take more product to meet thickness requirements than recoated or non porous substrates(metal, plastic, pre coated wood/sheetrock). TPR uses the attached procedure to measure wet film and dry film thickness....GET COATING MEASUREMENT PROCEDURE

AIRLESS SPRAYING

FIRESHELL®and TEMPROTEX™ Series Thermal Coatings :

| MODEL | SPECIFICATION | RECOMMENDED TIP |

| Graco 1095/ASM3100 | 1.15gpm/3300psi | 521 - 525* |

| Graco 695/ASM2700 | .94gpm/3300psi | 521 - 525* |

| SprayTech EPX2455 | .85gpm/3100psi | 521 - 525* |

| Titan 740IX | .72gpm/3100psi | 521 - 525* |

| Glidden Speedflo Power Twin | 1gpm/3000 psi | 521 - 525* |

| Glidden Speedflo Power Twin | 1.25gpm/3000 psi | 521 - 525* |

*Please contact Technical Support at 860-767-8773 for questions.

IP series, FR series, ME series (Paints):

| EQUIPMENT | HOSE SIZE | PRESSURE | TIP SIZE | MAX WFT/COAT |

| .6 gpm Airless | 1/4" X 25' | 3000 psi | 0.021 | 22 Mils |

HS series (Coatings):

| EQUIPMENT | HOSE SIZE | PRESSURE | TIP SIZE | MAX WFT/COAT |

| .6 gpm Airless | 1/4" X 25' | 3000 psi | 0.021 | 35 Mils* |

* For Non-Porous, Vertical Surfaces. Porous and/ or Ceilings will be less.

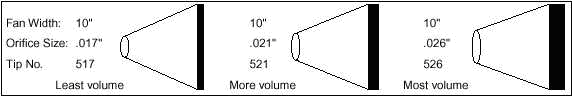

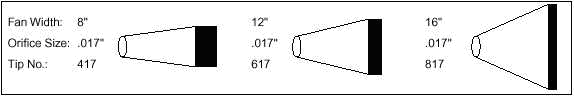

UNDERSTANDING AIRLESS SPRAY TIPS

The relationship of the tip opening (orifice) to spray pattern size is: Given a constant width (fan), the larger the orifice, the more material the sprayer will apply. (A larger orifice means greater paint flow).

Given a constant orifice size, an increasing fan width will apply a thinner coating of material to the surface because a given amount of material is distributed over a larger area.

Sizing a Spray Tip

U.S. manufacturers typically use three numbers to designate tip size, as in 517 or 211.

The first digit refers to fan width and is one-half the size of the working fan width. The second and third digits refer to orifice size in thousandths of an inch; thus, the 17 in 517 refers to an orifice size of .017 inches.

The following examples illustrate the tip numbering convention:

| TIP NUMBER | FAN WIDTH | ORIFICE SIZE |

| 217 | 4 inches | .017 inches |

| 423 | 8 inches | .023 inches |

| 527 | 10 inches | .027 inches |

Reversible tips are stamped on the top of the directional arrow for easy reference.

517

5 = 10" fan pattern at 12 inch spraying distance

17 = 17 thousandths orifice size

AIR SPRAYING

IP series, FR series, ME series (Paints):

- Binks 2001 gun or equivalent with a 68SS-68PB air cap ass'y and a 2 qt pressure cup.

- HVLP Gun (.070) fluid nozzle with 2Qt. pressure cup with 1.5 HP compressor & 6 CFM total air

HS series (Coatings):

- Binks 2001 gun or equivalent with a 68SS-68PB air cap ass'y and a 2 qt pressure cup.

- HVLP Gun (.070) fluid nozzle with 2Qt. pressure cup with 1.5 HP compressor & 6 CFM total air

AFES series (Flexible High Build Elastomerics):

- Binks 2001 gun or equivalent with a 68SS-68PB air cap ass'y and a 2 qt pressure cup.

- HVLP Gun (.070) fluid nozzle with 2Qt. pressure cup with 1.5 HP compressor & 6 CFM total air

- Binks 2001 gun or equivalent with a 68SS-68PB air cap ass'y and a 2 qt pressure cup.

- HVLP Gun (.070) fluid nozzle with 2Qt. pressure cup with 1.5 HP compressor & 6 CFM total air